|

The Premium Hot Standby redundancy offer, which is

compatible with Unity Pro software, ensures continuity of operation

for an automation system based on a Modicon Premium platform in the

event of failure of:

It is based on the “Primary/Standby” redundancy

principle, with complete redundancy of the main processing and

communication functions, the use of shared I/O on the Ethernet

TCP/IP network, a Modbus link and/or redundancy of in-rack I/O

(single-rack confi guration only).

Premium Hot Standby redundant architectures offer an

ideal solution for availability requirements when changeover time is

not critical. They are designed for processes which can tolerate a

lack of control on the part of the Premium PLC lasting up to one

second (average changeover time from the “Primary” unit to the

“Standby” unit and for updating shared I/O on Ethernet).

They can meet all availability requirements when the

purpose of the PLC is to monitor and control an installation in

continuous operation, signal incidents to a control station, and

transmit command instructions from the supervision manager to

various locations on an extensive site.

Example areas of application:

-

Centralized technical management of a public

facility (tunnel, airport, signals, etc.)

-

Control/monitoring of a water treatment or

distribution station

-

Electrical technical management

-

Hydroelectric power production

-

etc.

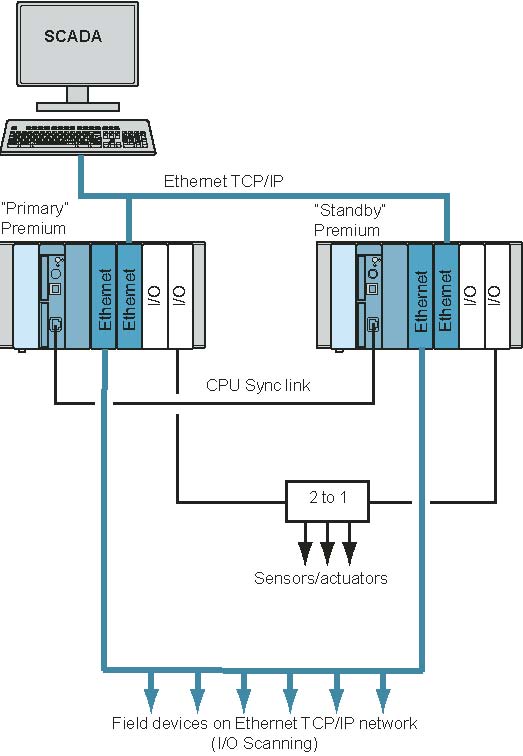

Principle

At the centre of the system, there are two Modicon

Premium single-rack configurations called the “Primary” PLC and the

“Standby” PLC. Their hardware and software configurations are

identical (i.e. identical modules in each rack). The offer comprises

two processor models (TSX H57 24M and TSX H57 44M) designed specifically

for Hot Standby architectures with Unity Pro software (version u

3.1). This dual processor configuration combines the functions of the

CPU and redundant coprocessor in the same unit.

The “Primary” PLC:

Executes the application program and manages the I/O,

which can take the form of:

-

Field devices on an Ethernet network managed by

the I/O Scanning service

-

Field devices on a Modbus master link

-

Sensors and actuators connected to Premium I/O

modules on bus X with single-rack configuration

Safeguards the transfer of all data via the “CPU

Sync” link to the “Standby” PLC at the start of every cycle.

In the event of a failure affecting the “Primary”

PLC, the standby system changes over automatically, whereby

execution of the application program and control of the I/O is

changed over to the “Standby” PLC within 1.5 cycles, with an

up-to-date data context.

An automatic mechanism for the assignment of “IP” and

“IP + 1” addresses changes the addresses of the Ethernet network

modules with the 2 Premium configurations which manage the field

devices. The same mechanism is used for “n” and “n + 1” slave

address assignments for Modbus link modules.

Once they have changed over, the “Standby” PLC

becomes the “Primary” PLC. Once the faulty PLC has been repaired and

reconnected to the standby system, it takes the role of the

“Standby” PLC.

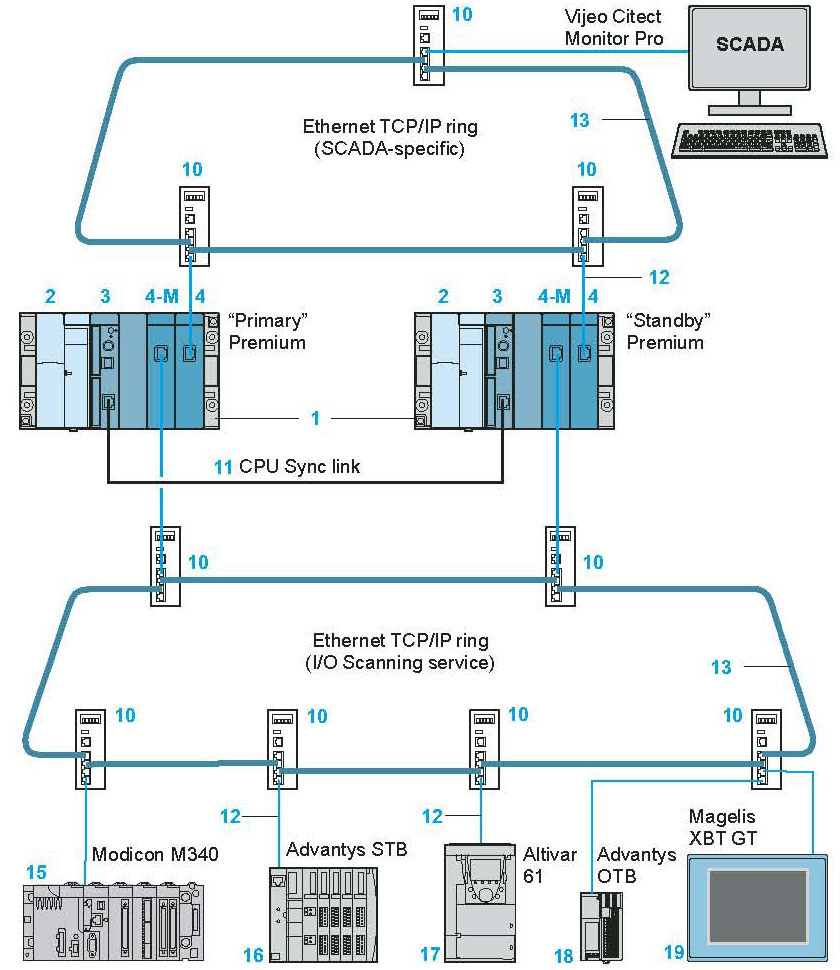

Architectures

Typical architecture

In this type of architecture, the I/O system in Premium PLCs

equipped with a dedicated Hot Standby TSX H57 24M/44M processor is

defined by the distribution of field devices or equipment on the

Ethernet TCP/IP network. From an operational point of view, the

following devices or equipment are connected on the same Ethernet

TCP/IP network:

-

Client: Twido controller, Modicon PLC,

Magelis HMI, W@de remote management module, etc.

-

Modbus TCP server: Advantys OTB/Momentum

distributed I/O, Advantys STB I/O islands, Altivar variable

speed drives, Lexium servo drives, Inductel/Ositrack

identification systems, etc.

The Ethernet I/O Scanning

service enables client-server exchanges between a PLC and Ethernet

equipment communicating by means of the Modbus TCP protocol. This

service can be used to define up to 64 periodic read or write

exchanges in the form of a configuration, based on tables of (word

type) variables for target devices or equipment. The I/O Scanning

service is a function that is available as standard with TSX ETY

4103/5103 Ethernet network modules.

Elements for redundancy

-

6, 8 or 12-position non-extendable rack TSX

RKY

-

Power supply module TSX PSY pppM

-

Premium Hot Standby processor TSX H57

24M/44M

-

Ethernet TCP/IP network module TSX ETY

4103/5103

(version >= sv 4.0)

Ethernet TCP/IP ring shared elements

-

Modicon M340 automation

platform featuring processor with built-in Ethernet port BMXP34

2020/2030

-

Advantys STB modular

distributed I/O with network interface module STB NIP 2212

-

Altivar 61/71 variable

speed drive with communication card VW3 A3 310

-

Advantys OTB Optimum

distributed I/O with interface module OTB 1E0 DM9LP

-

Magelis XBT GT graphic

terminal with on-board Ethernet port XBT GT pp30/40

Other possible shared

elements:

—Advantys FTM, IP 67 modular I/O

—Momentum distributed I/O -TSX ETG 100/1000 gateway for connecting

Modbus devices

—W@de remote management modules (RTU), designed for water

applications TSX HEW 315/320/330

—Inductel/Ositrack identifi cation system XGK S1715503 and XGK

Z33ETH

—Lexium servo drives with communication card

AMO ETH 001V000 -Preventa XPS MF compact and modular safety PLCs

Ethernet wiring elements:

-

ConneXium managed switch

with 2, 4 or 8 10/100BASE-TX ports TCS ESM 0p3

-

CPU Sync link, copper

crossover cable 490 NTC 000

-

Copper straight-through

cable 490 NTW 000

-

Copper crossover cable 490

NTC 000

【打印】【返回代理產品列表】【返回頂部】 |